Mivrag - End-to-End Manufacturing, Powered by Experts and Committed to Quality

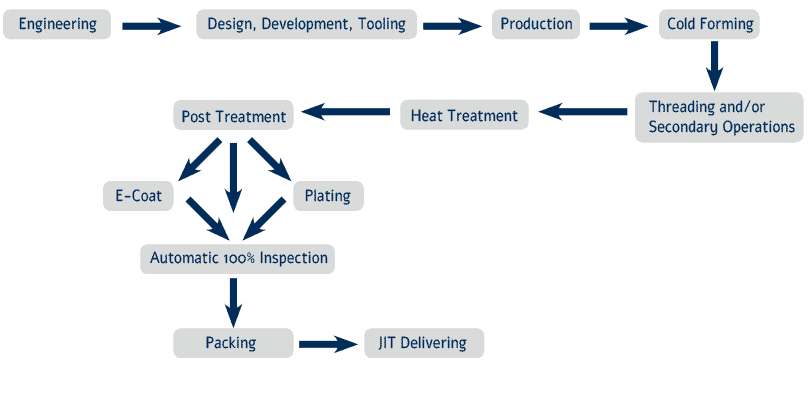

At Mivrag, we deliver a complete manufacturing value chain – from concept to delivery.

Our fast efficient production cycle includes product development, cold forming, secondary operations, heat treatment, advanced surface coating, quality testing, logistics, and final just-in-time (JIT) delivery.

With decades of hands-on experience in Cold Forging of steel parts, Mivrag offers a wide range of capabilities across every stage of production.

Our integrated approach ensures seamless transitions between engineering, manufacturing, and delivery – all under one roof.

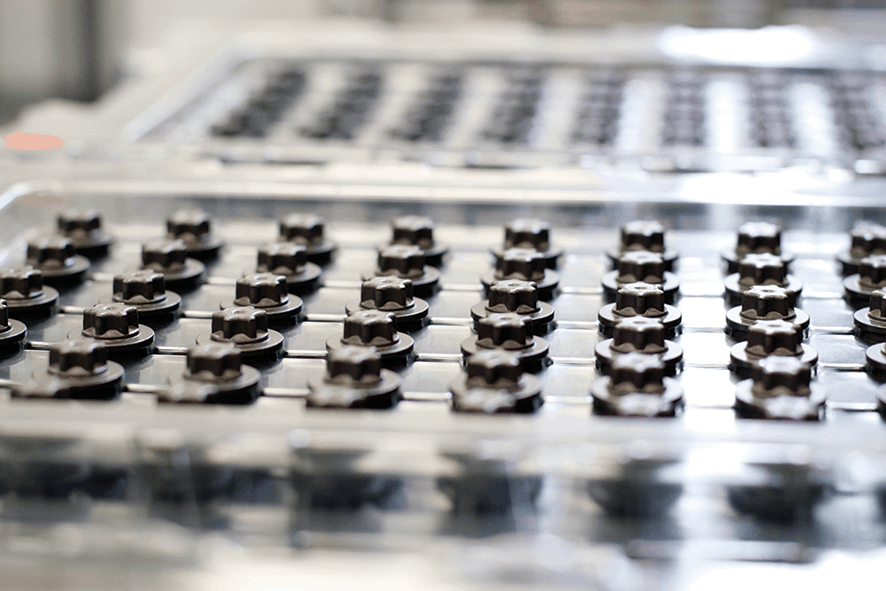

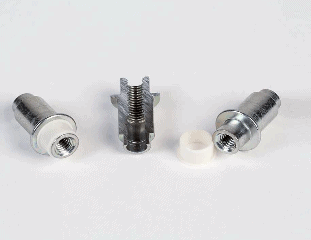

Cold Forming Expertise

Mivrag brings decades of proven experience in advanced Cold Forming technology, serving global automotive, industrial, and defense sectors. Our precision-engineered components are manufactured with efficiency, repeatability, and zero-defect reliability in mind.

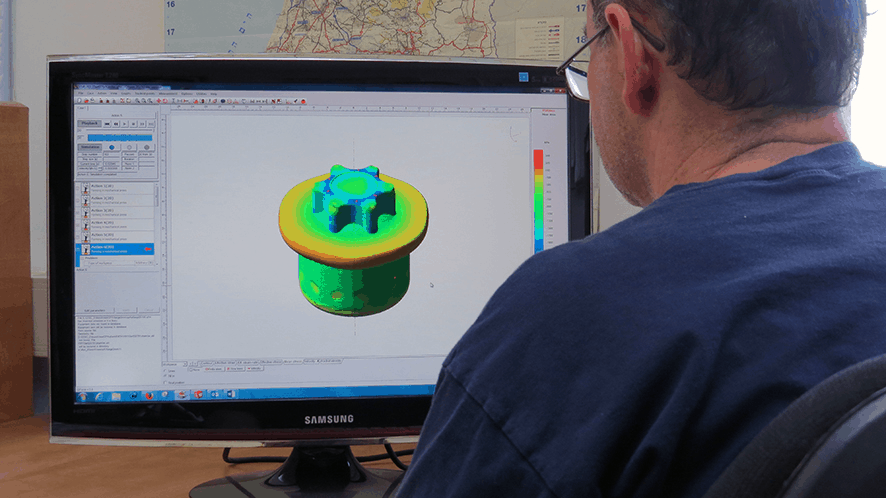

Engineering & Tooling Excellence

All engineering, design, and tooling processes are carried out in-house by Mivrag’s dedicated team of expert engineers and toolmakers. This full control over the production lifecycle allows for faster lead times, seamless prototyping, and customized solutions tailored to exact customer specifications.

Wide range of Materials & Size

We work with a wide range of materials, including carbon steel, stainless steel, brass, copper, and aluminum.

Our production capabilities support parts up to Ø40 mm in diameter and 180 mm in length, meeting the demands of both small and large-scale manufacturing.

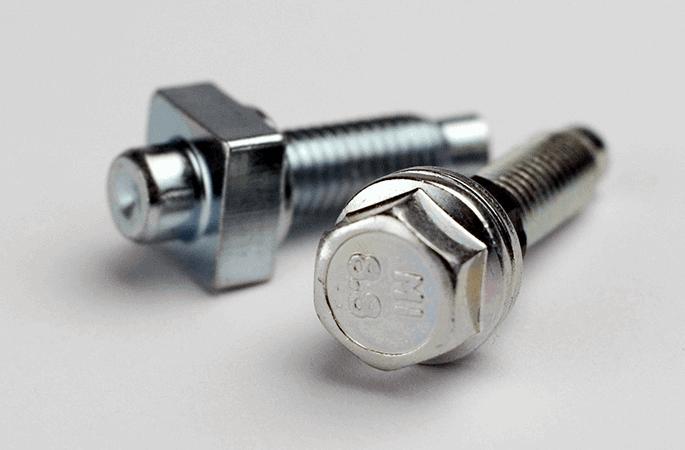

Precision Secondary Operations – Tailored to Your Needs

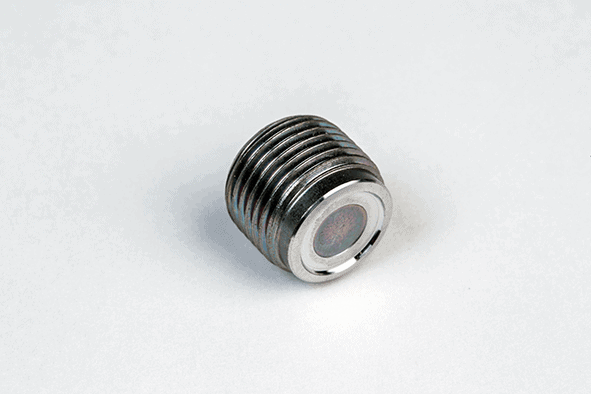

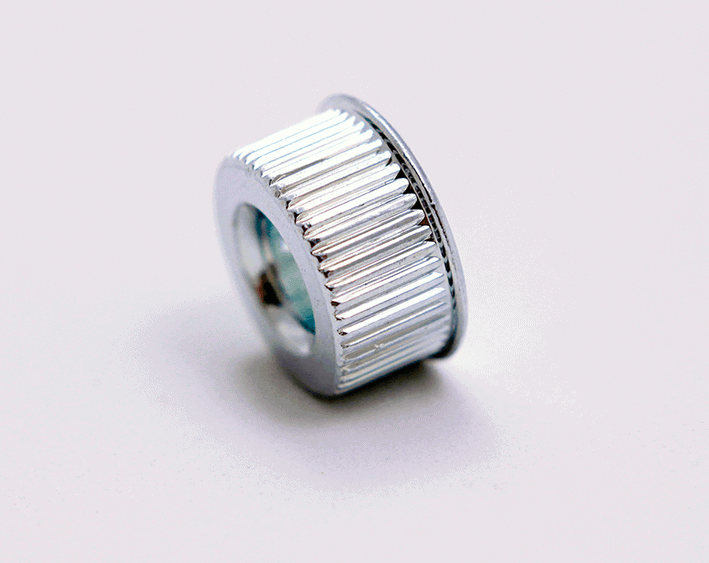

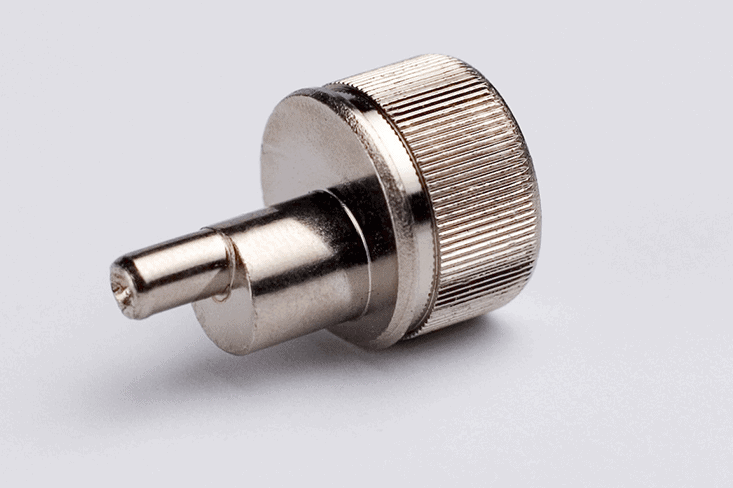

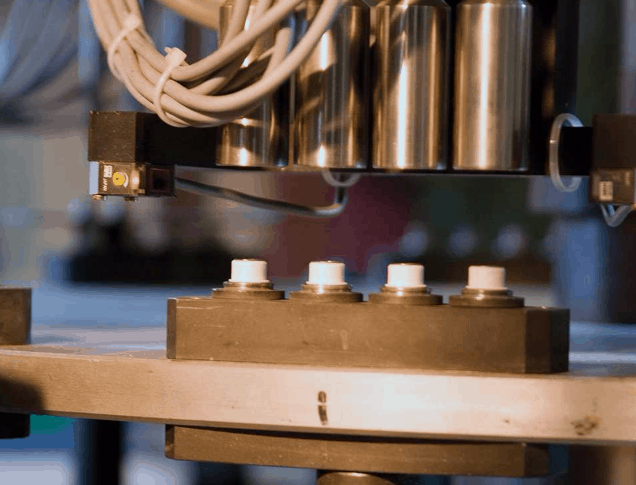

Following the cold forming process, Mivrag performs a wide range of secondary operations to meet exact customer specifications.

Our capabilities include machining, drilling, internal threading, milling, turning, thread rolling, cutting, grinding, and tapping.

With a broad array of advanced machinery, we deliver custom solutions with exceptional precision and efficiency, minimizing material waste and ensuring consistent quality in high-volume production.

Surface Treatment

Specific tailor-made solutions for high-quality surface – Shot pinning/Sandblast, Polishing.

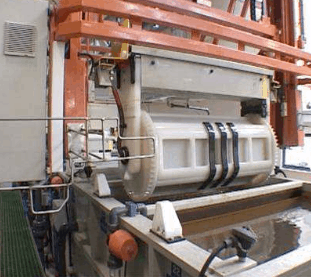

Cataphooretic plating line

Specific tailor-made solutions for high quality surface – Shot pinning/ Sand blast, Polishing.

Heat Treatment

Continuous state of the art furnace for neutral hardening and carburizing. Safedtm.

Zinc coating lines

2 barrel lines. Zinc, zinc-iron, zinc-nickel, zinc-phosphate. Stainless steel passivation.

Click here to read our Terms and Conditions for Price Quotation To learn more about our Zinc coating lines click here

All lines are equipped with advanced ecological and environmental systems that comply with Environmental Management Systems (ISO 14001:2015).

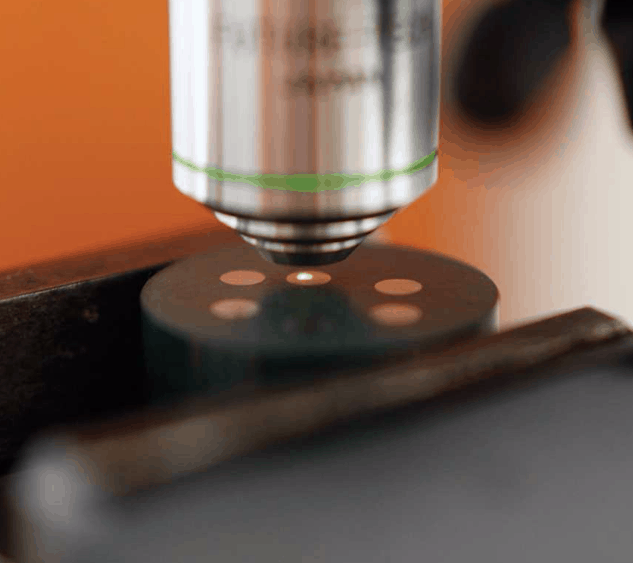

Advanced technology for optimal quality performance

Sorting

100% visual machine sorting.

100% Manual sorting department for top level parts.

Cleanliness

Clean rooms for supplying parts according cleanliness standards without particles larger than 150 µ.

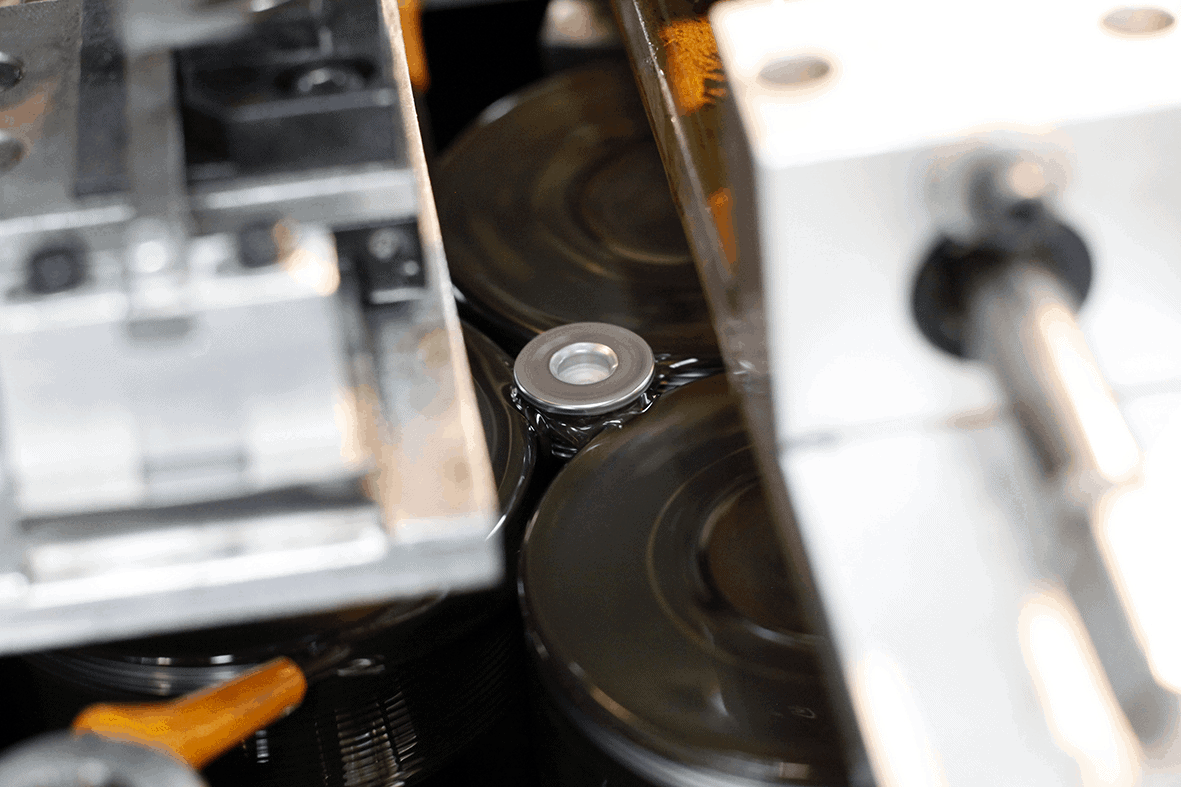

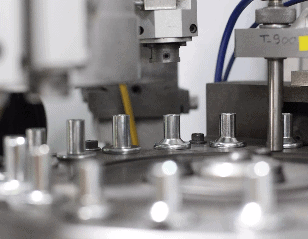

Assembly

Mivrag successfully designs, builds and implements automated assembly machines according to specific customer requirements.

Outstanding quality and continuous improvement serve as key objectives shared by the entire Mivrag team. Mivrag’s ability to consistently deliver the highest level of quality, coupled with competitive pricing and optimum service, has attained the company international recognition for outstanding performance in the automotive industry.